SORTING PLANTS

At IntaGrey, we specialise in delivering cutting-edge modular plants tailored to meet your specific sorting needs. Our typical workflow begins with you selecting the ideal sorting technology and conducting test work with sorting equipment manufacturers (OEMs) to ensure optimal performance. IntaGrey takes it from there, seamlessly integrating your chosen sorting technology into a highly efficient and reliable modular plant. With extensive experience and strong industry relationships, we can also connect you with trusted sorting companies to assist in the test work process. Explore our range of off-the-shelf modular plant solutions, designed for flexibility, precision, and ease of operation.

SENSOR BASED SORTING PLANTS - SINGLE SORTER PLANT

This state-of-the-art sensor-based sorting plant is designed for efficient material separation using a range of advanced sorting technologies. The system integrates a seamless workflow, beginning with a feed bin that ensures a controlled and consistent material flow onto the primary conveyor. This conveyor transports the material into a containerized sorting unit, where high-performance sorting machines identify and separate materials based on their unique characteristics.

At the core of the plant is a flexible, interchangeable sorting technology setup, allowing for adaptability in material processing. The system can accommodate various sorting methods, including X-Ray Transmission (XRT), Near-Infrared (NIR), Laser, UV, and other sensor-based technologies.

Once sorted, the materials are transferred onto two separate conveyors—one designated for the final product and the other for waste removal. This dual-conveyor system enhances efficiency by maximizing throughput while minimizing material loss.

Housed within a containerized unit, the sorting system offers a compact, transportable, and scalable solution that can be seamlessly integrated into various material processing operations. Designed for high precision, reduced manual handling, and increased operational efficiency, this plant is an ideal choice for industries requiring advanced and versatile material separation solutions.

- Pre-Processing: Materials are crushed, sized, and stockpiled before being fed into the plant via a feed bin using a front-end loader (FEL).

- Feed Control: The feed bin, equipped with a variable speed drive (VSD), ensures controlled feed rates and consistent operation through closed-loop control with a belt scale.

- Washing and Sorting: Material is washed through the fines screen feeder before entering the sorter. Effluent from washing is collected for disposal or further processing as needed.

- Tailings Management: Spillage, dribblings, and tailings are combined and conveyed to a tailings stockpile.

- Product Handling: Sorted product is ejected and stockpiled via a conveyor system.

- Auxiliary Systems: Compressed air equipment and motor control center (MCC) are housed in a nearby container for streamlined operations.

- Rapid Deployment – The plant is pre-engineered and modular, allowing for quick assembly and commissioning, even in remote locations.

- Lower Infrastructure Costs – Minimizes the need for extensive civil works and on-site construction, reducing overall project costs.

- Scalability & Flexibility – The modular design allows for easy expansion or relocation as project needs evolve.

- Efficient Operations – Designed for streamlined integration of sorting technology, optimising plant performance with minimal downtime.

The following are example applications that can be explored further with various sorting OEMs. Contact IntaGrey for referrals to industry-leading experts who can assist you.

- Diamond Recovery – A modular, containerized plant enables efficient diamond sorting at remote mining sites, reducing material transport and operational costs.

- Base and Precious Metals – The scalable design supports sorting operations for copper, lead, zinc, gold, and silver, with easy expansion as processing needs grow.

- Coal Processing – Modular plants provide a compact, efficient solution for destoning of coal reserves.

- Rare Earth & Industrial Minerals – The flexible plant configuration allows for customized sorting of lithium, tungsten, fluorite, and other critical minerals, ensuring rapid adaptation to different ore bodies.

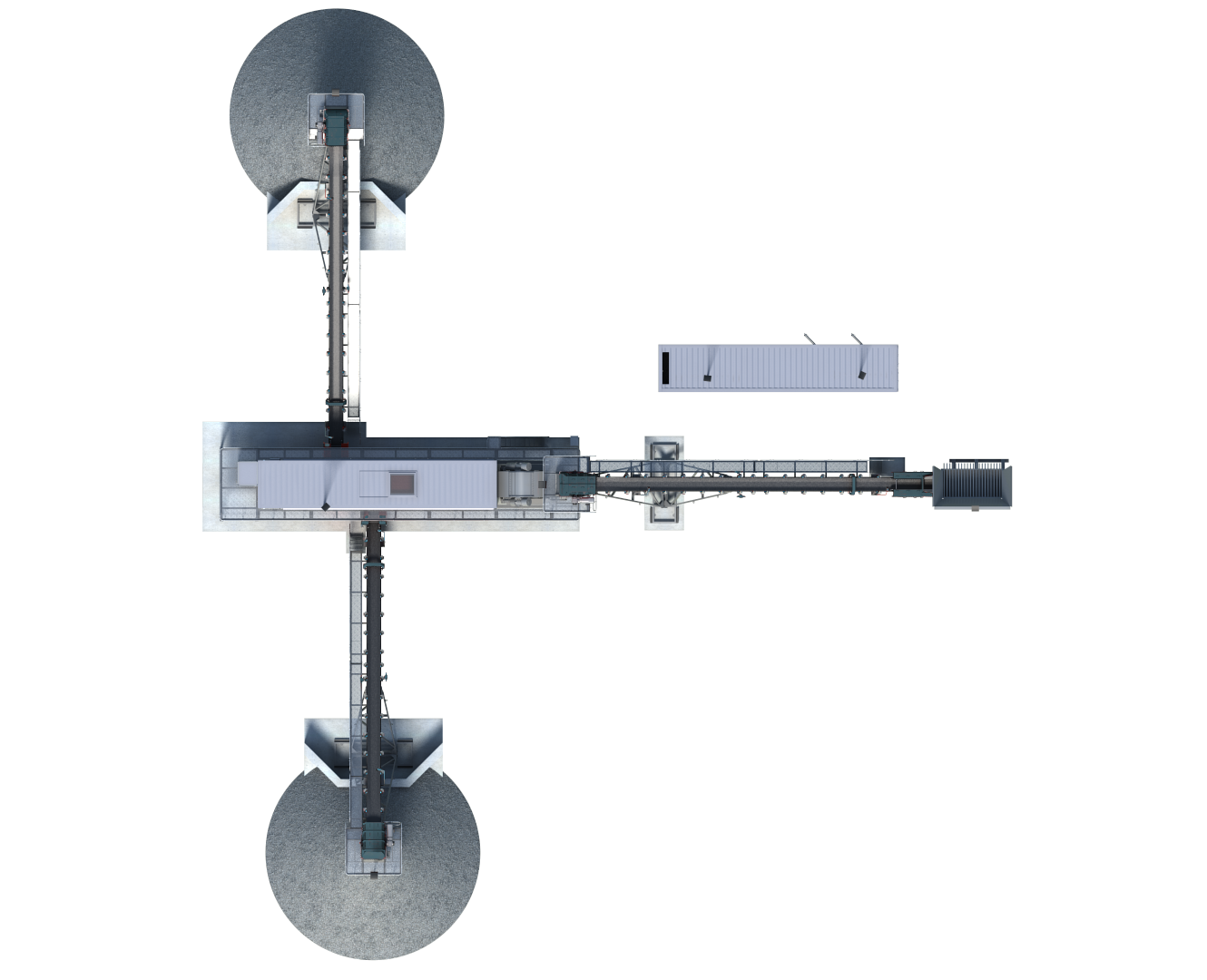

SENSOR BASED SORTING PLANTS - 4x SORTER PLANT

This state-of-the-art sensor-based sorting plant is designed for efficient material separation using a range of advanced sorting technologies. The process begins with a feed bin that ensures a controlled and consistent material flow onto a sizing screen. Here, undersized and oversized material is separated and directed to their respective stockpiles, while the correctly sized fraction continues to the sorting stage.

The screened material is then fed into two surge bins, ensuring a steady and controlled supply to four high-performance sorting machines. These machines utilize advanced sensor-based sorting technologies, such as X-Ray Transmission (XRT), Near-Infrared (NIR), Laser, and UV, to accurately identify and separate materials based on their unique properties.

Ejected material from all four sorting machines is directed onto a centralized discharge conveyor, which then transfers it onto a stockpile belt for final collection. The non-ejected material follows a similar streamlined process, combining onto a separate conveyor before being fed onto another stockpile conveyor.

Housed within a containerized unit, this modular sorting system offers a compact, transportable, and scalable solution suitable for various material processing operations. With its efficient material handling, high sorting precision, and reduced manual intervention, this plant provides an advanced and adaptable solution for industries requiring high-performance material separation.

· Pre-Processing: Materials are crushed, sized, and stockpiled before being fed into the plant via a feed bin using a front-end loader (FEL).

· Feed Control: The feed bin, equipped with a variable speed drive (VSD), ensures controlled feed rates and consistent operation through closed-loop control with a belt scale.

· Sizing & Surge Bins: Material is fed from the sizing screen, where undersize and oversize fractions are stockpiled, and the correct fraction is sent to two surge bins.

· Sorting & Washing: Material flows into the four sorting machines (for example XRT, NIR, Laser or UV) from the surge bins. The plant includes a washing stage, where material is washed before entering the sorter. Effluent from the washing process is collected for disposal or further processing as needed.

· Tailings Management: Ejected material from the sorters is conveyed to a stockpile, while non-ejected material is collected and conveyed to a separate stockpile. Spillage, dribblings, and tailings from all sorting machines are combined and conveyed to a dedicated tailings stockpile.

· Product Handling: Sorted product is ejected by the sorters, combined on a single conveyor, and transferred to a stockpile belt for final collection.

· Auxiliary Systems: Compressed air equipment and motor control center (MCC) are housed in a nearby container, ensuring streamlined operations.

- Rapid Deployment – The plant is pre-engineered and modular, allowing for quick assembly and commissioning, even in remote locations.

- Lower Infrastructure Costs – Minimizes the need for extensive civil works and on-site construction, reducing overall project costs.

- Scalability & Flexibility – The modular design allows for easy expansion or relocation as project needs evolve.

- Efficient Operations – Designed for streamlined integration of sorting technology, optimising plant performance with minimal downtime.

The following are example applications that can be explored further with various sorting OEMs. Contact IntaGrey for referrals to industry-leading experts who can assist you.

- Diamond Recovery – A modular, containerized plant enables efficient diamond sorting at remote mining sites, reducing material transport and operational costs.

- Base and Precious Metals – The scalable design supports sorting operations for copper, lead, zinc, gold, and silver, with easy expansion as processing needs grow.

- Coal Processing – Modular plants provide a compact, efficient solution for destoning of coal reserves.

- Rare Earth & Industrial Minerals – The flexible plant configuration allows for customized sorting of lithium, tungsten, fluorite, and other critical minerals, ensuring rapid adaptation to different ore bodies.

SENSOR BASED SORTING PLANTS - DOUBLE SORTING PLANT

This state-of-the-art sensor-based sorting plant is designed for efficient material separation using a range of advanced sorting technologies. The process begins with two feed bins, each ensuring a controlled and consistent material flow. The material from each bin is fed into separate sorting machines, with each machine typically handling different size fractions. These high-performance machines use sensor-based technologies (such as XRT, NIR, Laser, and UV) to identify and separate materials based on their unique properties.

The material is sorted by the two machines, with the ejected material directed onto separate discharge conveyors, which then transfer it to stockpile belts. The non-ejected material from both machines is combined onto a single conveyor and directed to another stockpile belt for further processing or disposal.

Housed within a containerised unit, this modular sorting system offers a compact, transportable, and scalable solution suitable for various material processing operations. Designed for high precision, reduced manual handling, and increased operational efficiency, this plant provides an advanced and adaptable solution for industries requiring high-performance material separation.

· Material Feeding: Two feed bins ensure controlled and consistent material flow into the sorting system.

· Sorting Process: Each feed bin supplies material to a separate sorting machine. Machines typically handle different size fractions of the material. Sorting is done using advanced sensor technologies (XRT, NIR, Laser, UV).

· Ejected Material Handling: Ejected material from each machine is directed onto separate discharge conveyors, then transferred to stockpile belts.

· Non-Ejected Material Handling: Non-ejected material from both machines is combined onto a single conveyor and sent to another stockpile belt.

- Rapid Deployment – The plant is pre-engineered and modular, allowing for quick assembly and commissioning, even in remote locations.

- Lower Infrastructure Costs – Minimizes the need for extensive civil works and on-site construction, reducing overall project costs.

- Scalability & Flexibility – The modular design allows for easy expansion or relocation as project needs evolve.

- Efficient Operations – Designed for streamlined integration of sorting technology, optimising plant performance with minimal downtime.

The following are example applications that can be explored further with various sorting OEMs. Contact IntaGrey for referrals to industry-leading experts who can assist you.

- Diamond Recovery – A modular, containerized plant enables efficient diamond sorting at remote mining sites, reducing material transport and operational costs.

- Base and Precious Metals – The scalable design supports sorting operations for copper, lead, zinc, gold, and silver, with easy expansion as processing needs grow.

- Coal Processing – Modular plants provide a compact, efficient solution for destoning of coal reserves.

- Rare Earth & Industrial Minerals – The flexible plant configuration allows for customized sorting of lithium, tungsten, fluorite, and other critical minerals, ensuring rapid adaptation to different ore bodies.

SENSOR BASED SORTING PLANTS - DIAMOND SORTING

This state-of-the-art diamond sorting plant is designed for efficient and secure material separation using X-Ray Transmission (XRT) technology. Ideal for a diamond start-up operation with batch treatment of sized material fractions, the system ensures precision sorting with a streamlined workflow. Sized material is fed from a controlled feed bin directly into the XRT sorting machine, where high-resolution sensors detect and separate diamonds from waste.

Once sorted, the concentrate is transferred into a secure recovery area, where it is hand-sorted inside a glovebox for added security. Recovered diamonds are safely placed into a secure storage unit, while glovebox tailings are conveyed to a designated red area, where they are stockpiled for future reprocessing.

Housed within a modular and transportable unit, this plant offers a compact, efficient, and scalable solution for diamond recovery operations. Designed for high precision, security, and operational efficiency, it provides an ideal system for diamond startups or bulk sampling plants and specialised batch processing applications.

- Material Feeding: Sized material is fed from a controlled feed bin into the XRT sorting machine.

- Sorting Process: XRT technology detects and separates diamond-bearing material from waste.

- Recovery Area: Sorted concentrate is transferred to a secure recovery room. Hand sorting is performed inside a glovebox for added security. Recovered diamonds are placed into a secure storage unit.

- Tailings Management: Glovebox tailings are conveyed to a designated red area. Tailings are stockpiled for future reprocessing.

- Rapid Deployment – The plant is pre-engineered and modular, allowing for quick assembly and commissioning, even in remote locations.

- Lower Infrastructure Costs – Minimizes the need for extensive civil works and on-site construction, reducing overall project costs.

- Scalability & Flexibility – The modular design allows for easy expansion or relocation as project needs evolve.

- Efficient Operations – Designed for streamlined integration of sorting technology, optimising plant performance with minimal downtime.

Diamond Recovery – A modular, containerised plant enables efficient diamond sorting at remote mining sites, reducing material transport and operational costs.

SENSOR BASED SORTING PLANTS - DIAMOND EXPLORATION PLANT

This state-of-the-art diamond sorting plant is designed for efficient and secure material separation using X-Ray Transmission (XRT) technology. Ideal for diamond exploration and recovery, the plant processes raw material through screening, washing, and classification before advanced sorting technology extracts diamond-bearing material. The sorted concentrate is carefully collected, hand-sorted in a secure environment, and safely stored, while tailings are reintroduced into the system to optimize resource recovery. With a streamlined, modular, and transportable design, the plant offers high precision, efficiency, and reliability, making it a valuable solution for exploration and small-scale diamond operations.

- Material Handling & Screening:

- Unsized material is fed into the plant, where oversize particles are removed by grizzly bars and a sizing screen.

- The remaining material is washed in a scrubber.

- Water Treatment:

- Fine particles are processed through a degrit system, with certain fractions stockpiled.

- Settled fines are bagged for removal.

- Size Classification & Treatment:

- Larger material is classified into surge bins and batch-treated through a dryer and diamond sorting machine.

- Diamond Concentrate Handling:

- Sorted concentrate is collected, hand-sorted, and secured in a drop safe.

- Tailings are reintroduced into the system for closed-loop processing.

- Plant Throughput:

- Capacity depends on particle size distribution, with a scrubbing capacity of 10 tph.

- Higher Diamond Recovery Rates – Enhances the efficiency of diamond extraction by detecting and recovering even low-grade or coated stones.

- Reduced Processing Costs – Lowers energy and water consumption by accurately ejecting diamonds with minimal waste ejection.

- Sustainability – Minimises environmental impact by decreasing tailings, water usage, and the need for chemical treatment.

- Improved Diamond Concentrate Quality – Delivers less diluted concentrate to the recovery stage, optimizing sorting efficiency and overall plant performance.

- Diamond Recovery – Detects and separates diamonds from kimberlite ore.

- Remote exploration sites – Cost effective solution for doiung diamond exploration on site compared to transporting large samples to laboratories.

- Recovery Module for Future Expansion – This plant can be used as a recovery module when expanding to a production plant.

SENSOR BASED SORTING PLANTS - 2 STAGE SORTING PLANT

This state-of-the-art sorting plant is designed for efficient material separation using various sensor-based sorting technologies. The process begins with a feed bin that ensures a steady and controlled flow of material into the system. As the material moves through, it is screened and separated into different size fractions, with only the most suitable portion advancing for further processing. The sorting process occurs in two stages: an initial phase that removes the bulk of unwanted material, followed by a secondary stage that refines the output by either extracting additional waste or targeting specific products. Once sorted, the material is either directed to the next phase of processing or removed and stockpiled. In general, a smaller percentage of material is separated out, while the majority continues through the system, maximizing efficiency and resource recovery.

- Material Feeding: A feed bin ensures a controlled and consistent flow of material into the sorting system.

- Material Sizing: The material passes over a sizing screen, separating it into two or three fractions. The oversized and undersized fractions are stockpiled, while the target sorting size fraction moves forward to the primary sorting stage.

- Sorting Process: The sorting process consists of two stages in series. The primary stage typically focuses on waste removal, while the secondary stage either removes additional waste or targets specific products.

- Ejected and Non-Ejected Material Handling: Ejected and non-ejected material is either fed into the next stage of processing or removed and stockpiled. As a general rule, the smaller percentage of material in the feed is ejected, while the larger percentage remains in the process.

- Rapid Deployment – The plant is pre-engineered and modular, allowing for quick assembly and commissioning, even in remote locations.

- Lower Infrastructure Costs – Minimizes the need for extensive civil works and on-site construction, reducing overall project costs.

- Scalability & Flexibility – The modular design allows for easy expansion or relocation as project needs evolve.

- Efficient Operations – Designed for streamlined integration of sorting technology, optimising plant performance with minimal downtime.

The following are example applications that can be explored further with various sorting OEMs. Contact IntaGrey for referrals to industry-leading experts who can assist you.

- Diamond Recovery – A modular, containerized plant enables efficient diamond sorting at remote mining sites, reducing material transport and operational costs.

- Base and Precious Metals – The scalable design supports sorting operations for copper, lead, zinc, gold, and silver, with easy expansion as processing needs grow.

- Coal Processing – Modular plants provide a compact, efficient solution for destoning of coal reserves.

- Rare Earth & Industrial Minerals – The flexible plant configuration allows for customized sorting of lithium, tungsten, fluorite, and other critical minerals, ensuring rapid adaptation to different ore bodies.

Dense Medium Separation (DMS) Plant